Madison Outlet has the following inventory transactions for the year, showcasing a comprehensive range of activities that impact its inventory management. These transactions encompass various types, valuation methods, management strategies, and analytical techniques, providing a holistic view of the company’s inventory operations.

The diverse inventory transactions at Madison Outlet reflect the complexities of modern supply chain management, highlighting the need for effective inventory control to optimize operations and maximize profitability.

Inventory Transactions

Madison Outlet engages in various inventory transactions throughout the year. These transactions include:

- Purchases:When Madison Outlet acquires inventory from suppliers, it records a purchase transaction.

- Sales:When Madison Outlet sells inventory to customers, it records a sales transaction.

- Returns:When customers return purchased items, Madison Outlet records a return transaction.

- Adjustments:When there are errors or losses in inventory, Madison Outlet records an adjustment transaction.

- Transfers:When Madison Outlet moves inventory between different locations, it records a transfer transaction.

Inventory Valuation

Madison Outlet uses the following methods to value its inventory:

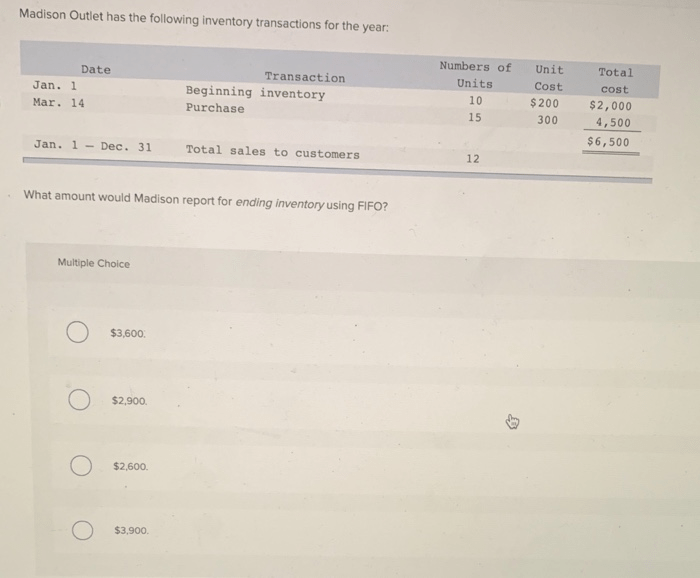

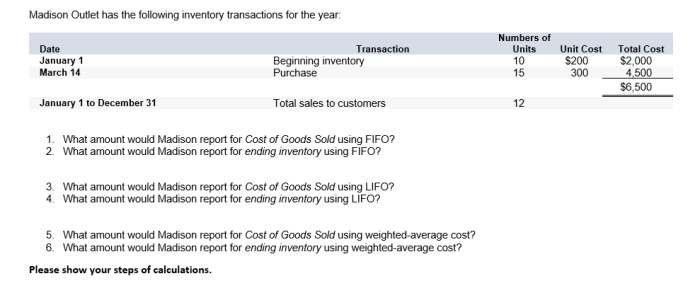

First-In, First-Out (FIFO)

FIFO assumes that the first items purchased are the first ones sold. This method results in the cost of goods sold being based on the oldest inventory costs. Advantages of FIFO include simplicity and compliance with GAAP. However, it can overstate inventory value during periods of inflation.

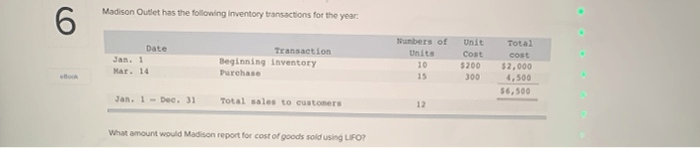

Last-In, First-Out (LIFO)

LIFO assumes that the last items purchased are the first ones sold. This method results in the cost of goods sold being based on the most recent inventory costs. Advantages of LIFO include reducing taxable income during periods of inflation and providing a more conservative estimate of inventory value.

However, it can understate inventory value during periods of deflation.

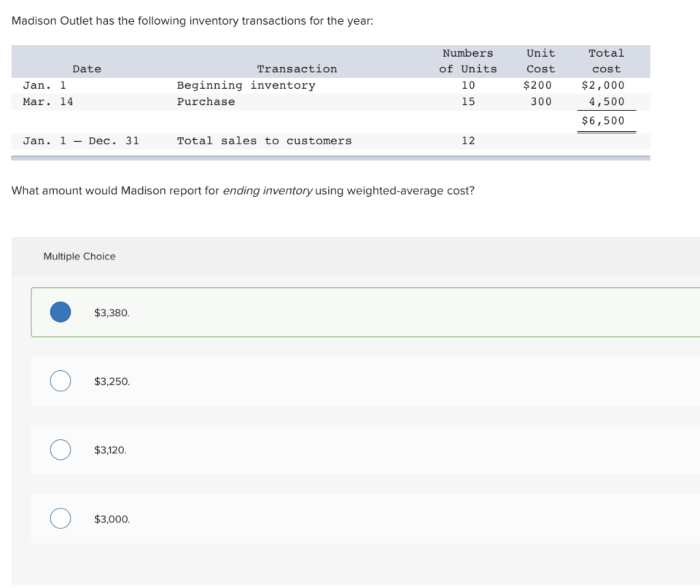

Weighted Average Cost (WAC), Madison outlet has the following inventory transactions for the year

WAC calculates the average cost of inventory by dividing the total cost of inventory by the total number of units. This method provides a more stable cost of goods sold than FIFO or LIFO. However, it can be more complex to calculate.

Inventory Management: Madison Outlet Has The Following Inventory Transactions For The Year

Effective inventory management is crucial for Madison Outlet to:

- Meet customer demand:Ensure that the right products are available in the right quantities to meet customer needs.

- Minimize costs:Reduce inventory carrying costs, such as storage, insurance, and handling.

- Improve efficiency:Optimize inventory levels to reduce waste and improve operational efficiency.

- Increase profitability:Manage inventory effectively to maximize sales and profits.

Key factors to consider in inventory management include:

- Demand forecasting:Predicting future customer demand to determine appropriate inventory levels.

- Lead time:The time it takes to receive inventory from suppliers.

- Safety stock:Additional inventory held to buffer against unexpected demand or supply disruptions.

- Inventory turnover:The rate at which inventory is sold and replaced.

Inventory Analysis

Madison Outlet can analyze its inventory transactions to identify trends and patterns. This analysis can help the company:

- Improve inventory accuracy:Identify and correct errors in inventory records.

- Optimize inventory levels:Determine appropriate inventory levels to meet demand without overstocking or understocking.

- Reduce waste:Identify slow-moving or obsolete inventory and implement strategies to reduce losses.

- Improve customer service:Ensure that products are available to meet customer needs and reduce the risk of stockouts.

Metrics used for inventory analysis include:

- Inventory turnover ratio:Measures the number of times inventory is sold and replaced during a period.

- Days sales in inventory (DSI):Measures the average number of days it takes to sell inventory.

- Gross profit margin:Measures the profitability of inventory sales.

Inventory Optimization

Madison Outlet can use various strategies to optimize its inventory levels:

- Just-in-time (JIT) inventory:Minimizing inventory levels by receiving inventory only when needed.

- Vendor-managed inventory (VMI):Allowing suppliers to manage inventory levels based on customer demand.

- Consignment inventory:Holding inventory for suppliers and only paying for it when it is sold.

- Safety stock optimization:Determining the optimal level of safety stock to minimize the risk of stockouts.

Benefits of inventory optimization include:

- Reduced inventory carrying costs:Lowering storage, insurance, and handling expenses.

- Improved cash flow:Reducing the amount of capital tied up in inventory.

- Increased efficiency:Streamlining inventory processes and reducing waste.

- Enhanced customer satisfaction:Ensuring product availability and reducing the risk of stockouts.

Expert Answers

What are the different types of inventory transactions?

Madison Outlet’s inventory transactions may include purchases, sales, returns, write-offs, and adjustments.

How does Madison Outlet value its inventory?

Madison Outlet can use various valuation methods, such as FIFO, LIFO, or weighted average cost, to determine the value of its inventory.

Why is effective inventory management important for Madison Outlet?

Effective inventory management helps Madison Outlet optimize stock levels, reduce costs, improve customer service, and enhance overall profitability.